A Business Guide to the Types of pH Controllers and their Applications

pH dosing systems, also known as pH control systems, are highly automated devices capable of measuring, adjusting and monitoring a range of water properties. These systems are widely used in commercial and industrial applications, including trade waste and recycling water applications.

A pH controller is a low-risk, high return investment.

Cleanawater offers two types of pH controllers, inline and recirculating pH control systems, each designed to suit different budget and flow rate requirements.

Cleanawater’s pH dosing systems can be easily integrated into existing installations, and can be coupled with other systems to provide an all-in-one water treatment solution.

These solutions are designed to maximise utility and reduce cost with a minimal system footprint. When combined with after-sales support, a pH controller from Cleanawater is a low-risk, high return investment for your business.

Contact Cleanawater's expert team for recommendation and installation of efficient and accurate pH controllers.

Features of Cleanawater pH Controllers

- Factory assembled and supplied as a ’plug-and-play’ solution

- Wide selection of probes, dosing pumps and chemicals to suit varying flow rates and water authority requirements

- Remote alarm systems, including SMS notification

- Easily combined with other Cleanawater systems such as Oil Water Separators, Water Recycling Systems and First Flush Diversion Systems

Industry Examples

Scenario 1: Water recycling monitoring in mining site

A coal mining site has approached Cleanawater to commission a water system able to sanitise water and ensure correct pH levels for water recycling purposes.

Recycled water will be used for cleaning of light and heavy duty vehicles that operate on-site. It is crucial to the business that water is safe to use for humans, and vehicles will not be damaged by acid water. In addition to standard pH dosing and controller system, the mine management team has commissioned an alarm system to be installed in order to ensure smooth pH correction.

Solution: Cleanawater’s Chlorine dosing and pH control system

This highly advanced system uses chlorine sanitation to ensure pathogens are eradicated, and a pH control system ensures pH levels are safe for human and equipment use. The alarm system ensures operators and managers are notified when an error occurs, thus ensuring minimal downtime in the event of a fault.

Scenario 2: Food Processing

A food processing plant has recently expanded its services to process different products. The change, however, has resulted in a waste water reading of 4 pH, which is below the legal pH threshold for discharge. The business has been advised to contact an industry expert to commission a pH correction system.

Solution: Cleanawater’s inline pH Control System with a solenoid metric dosing pump.

Cleanawater delivers an inline pH correction system that is capable of adjusting the pH level of water to comply with the regulation. This pH dosing system is a cost-effective solution due to minimum maintenance requirements and the availability of low-cost consumables.

An overview of pH controllers

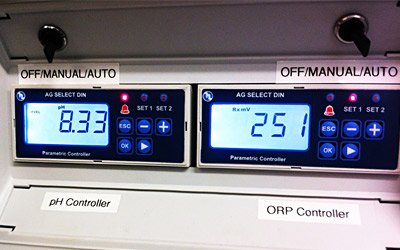

pH monitors, or pH dosing systems, are devices that monitor, measure and adjust a number of substance properties, including pH levels, residual chlorine and temperature. Cleanawater can provide two types of pH Control Systems: an Inline pH Control System, and a Recirculating pH Control System.

In order to suit different dosing requirements, three types of dosing pumps are available for pH control:

- Peristaltic pumps are only able to inject small amounts of chemicals, making them suitable when low injection rates are required.

- Solenoid metric pumps are capable of handling medium injection rates, and are highly accurate in chemical injection.

- Motor driven pumps are used when high injection rates are required.

How pH Control Systems measure Chlorine levels

The direct measurement of chlorine levels in a substance requires sophisticated and expensive equipment. In order to accurately and economically measure chlorine levels in water, a measurement called RX (also known as ORP) is used. RX is able to measure both free and total chlorine levels in water. These values are important as they determine whether the desired final concentration of chlorine has been achieved.

RX (ORP)

Oxidation Reduction Potential (ORP) or Redox (RX) is used to represent the oxidising or reducing nature of a substance. Oxidisers, which accept electrons, and reducers, which lose electrons, operate in a similar way as alkalinity and acidity; an increase in oxidisers results in a decrease in reducers. The presence of electrons in water determines its conductivity, which is measured and then interpreted to obtain chlorine levels.

Similarly to pH, which is measured by determining the negative logarithm of concentration of Hydrogen Ions in a substance, a substance with a high concentration of oxidisers will return a positive OPR reading.

Type 1: Inline pH Control System

Inline pH control systems receive their name from the way in which probing and correction of water properties is executed. Generally, inline pH controllers obtain information from a probe, and adjust water properties accordingly.

Two types of probes are available for inline pH control systems: a submersible probe, and an upstream probe. When a submersible pump is used, the readings from this pump are sent to a controller which activates the dosing pump. Chemicals from the dosing pump are injected upstream.

When an upstream probe is used, chemicals are injected directly into the holder tank.

Inline pH control systems are a cost-effective way to monitor and adjust water properties, however, these systems are less accurate and have a series of limitations when compared to recirculating pH controllers.

Using a submersible probe may expose the probe to contamination. Some of the different chemicals added to the water have different specific gravity values, which means that after a period of time, these chemicals settle to the bottom, thus compromising the accuracy of the probe’s reading. For example, caustic chemicals, settle to the bottom of the pit after some time. If this occurs, the probe could constantly detect high levels of causticity, which could be an inaccurate reading.

To overcome this limitation, a mechanical agitator can be installed in the retention tank, however, this results in a more expensive system. While there are some limitations, inline systems are an excellent fit for scenarios where allowable pH levels sit within a flexible range. This may be the case in an industrial trade waste agreement, where pH levels are generally required to be between 7 and 10.

Recirculating pH Control System

Recirculating systems are ideal for scenarios where measurement accuracy is paramount.

A water recycling system is one example where accuracy is extremely important. Water is drawn from the treatment tank by a pump, and is fed through a cartridge filter to ensure that the water sample is clean. Once filtered, water passes travels to a gallery where probes are able to measure different properties of the water.

Information collected by the probes is sent to a digital controller which determines whether corrections are required. Depending on the necessary adjustments, the controller calculates the amount of chemical needed and activates the pump that controls that chemical. This chemical is then injected into the water and the water is returned to the retention tank. As its name indicates, water is constantly circulating through the pH Control system, which allows water to be sampled regularly in order to ensure any adjustments made were correct.

Recirculating systems are commonly used in large scales in pools, as the required pH level is critical. Recommended pH levels in public pools are between 7.2 and 7.8 - this is a range where chlorine is effective as a sanitation method and no discomfort is caused to human skin or eyes. In addition to the previously mentioned consequences for non-compliant pH levels, water may also appear visibly dirty when at certain pH levels. In a pool setting, cloudy water is undesirable as it may be perceived as polluted.

Although recirculating systems typically operate using two dosing pumps and two chemicals, Cleanawater is capable of easily introducing additional probes and dosing pumps to target specific needs.

Contact Cleanawater for more information about water recycling and treatment solutions.

We offer highly technical expertise, excellent quality equipment and a personalised approach to your business’ needs. We can easily combine our solutions to suit your specific business, compliance and investment requirements.

Looking for efficient solutions for water authority compliance? Cleanawater can recommend and install a range of eco-friendly solutions, including pH controllers.

Must Read

VapourGard: Your ultimate odour control solution

Control odours effectively and safely with CleanaWater's VapourGard system. Ideal for industries such as mining, landfill operations, recycling, and more, the VapourGard system uses lightweight partic ...

Read moreControl Odour with VapourGard

Control odours effectively and safely with CleanaWater's VapourGard system. Ideal for industries such as mining, landfill operations, recycling, and more, the VapourGard system uses lightweight partic ...

Read more