Using the right pre-treatment for wastewater compliance

Removing oils and greases from wastewater is critical for the protection of the environment. This must be done before discharging water into a sewer in order to comply with Australian regulations. However, different industries and applications have different concentrations of oils and greases in their wastewater.

How do you know which is the best method to remove oils and grease from wastewater? People talk of both grease interceptors and oil separators. What is the difference between them, and which one should you consider for your business?

Contact Cleanawater for advice about oil water separators and where to use them.

What is a grease interceptor?

A grease interceptor is a basic form of equipment for separating grease and oils from water. It is shaped like a box and includes a:

- Baffle plate

- Solids compartment

- Separation area

The baffle plate slows down the flow of water and reduces turbulence. This allows solids to drop out into the solids compartment. The separation area allows for oil to float to the surface of the water.

Discharge water is drawn from an outlet below the surface, preventing oil from being carried over into a sewer. The resulting wastewater is largely clean from solids and oils.

Grease interceptor solids compartments must be cleaned out regularly to prevent blockages. As a general rule of thumb, clean the compartment out when it reaches 25 per cent of its capacity. Some users set a time-based cleaning schedule, based on the capacity of the facility.

What is an oil separator?

Oil separators are more advanced forms of equipment for separating oil from water. They have internal structures that facilitate the binding of oil droplets together.

The retention time of the water inside the separator is much longer than that for a grease interceptor, allowing more time for the separation to occur. This causes the removal of more oil from the water stream. Oil separators also have higher capacity ratings meaning that they can be used for much higher water flow rates than grease interceptors.

However, it is important that only quick-break degreasers are used in the business concerned. Other degreasers prevent oil droplets from forming and separating from the water. This makes the oil separator ineffective and has the potential to allow oil to escape into the trade waste sewer.

Choosing between a grease interceptor and an oil separator

Grease interceptors are typically used in applications where there is the potential for blocking. This includes commercial kitchens and restaurants where fatty materials can solidify in drain lines. The solids compartment of a grease trap ensures that solid waste is removed from the drain — preventing blockages.

Oil separators are used in industrial environments where there is the potential for oil and other hydrocarbons to be carried into the wastewater stream. Applications include car washes, mining sites, workshops, industrial sites, service stations, and manufacturing sites.

In summary:

- Grease interceptors have a primary function of removing fatty solids from wastewater. They are most often used in commercial kitchens or similar applications.

- Oil separators have a primary function of removing liquid oil from wastewater. They are most often used in manufacturing or industrial applications.

Wastewater compliance

All businesses that discharge wastewater are required to have a trade waste permit issued by their local water authority. The permit specifies pre-treatment conditions, which may include the use of grease interceptors or oil separators. These permits also set specific limits for wastewater contaminants.

Pre-treatment solutions must be implemented before wastewater is accepted from the business into the trade waste sewer network. Contact your local water authority before discharging wastewater for more information.

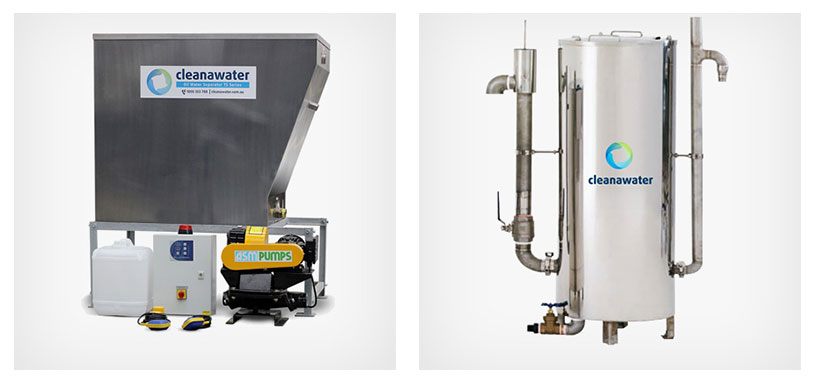

Oil separators from Cleanawater

Cleanawater supplies oil separators to clients all over Australia. We offer two main types of separator:

- Coalescing Plate Separators: Ranging in capacity from 1,000 litres to 50,000 litres, these remove oil from water up to 10 ppm.

- Vertical Gravity Separators: With a capacity from 700 litres to 3,000 litres, these remove oil from water down to 50 ppm. Their compact design and hot water handling unit makes them suitable for use in commercial kitchens as well as in more robust industrial environments.

Regulators also require that pre-treatment solutions are regularly serviced and maintained. Cleanawater provides maintenance and servicing contracts as part of our offering to customers. This helps to preserve the performance of your oil separator. It is an important aspect of compliance and responsible environmental care.

Talk to Cleanawater for expert advice

Contact Cleanawater for all your oil water separator needs. We have more than 20 years of experience and can advise you on the best solution for your business.

Contact Cleanawater to find out more about oil water separators.

Must Read

VapourGard: Your ultimate odour control solution

Control odours effectively and safely with CleanaWater's VapourGard system. Ideal for industries such as mining, landfill operations, recycling, and more, the VapourGard system uses lightweight partic ...

Read moreControl Odour with VapourGard

Control odours effectively and safely with CleanaWater's VapourGard system. Ideal for industries such as mining, landfill operations, recycling, and more, the VapourGard system uses lightweight partic ...

Read more