Wash bay water treatment for wastewater compliance

Wash bays generate wastewater containing oil and grease from the vehicles that they clean. Local councils and water authorities set parameters for how this wastewater must be processed before it can be discharged into the sewerage system.

The primary requirement is for an oil water separator which removes oil from the water to within acceptable limits. But, some chemicals used by wash bays could affect the performance of oil water separators leading to oil passing through the oil separator into the sewerage system. Any environmental incident of this nature could lead to environmental damage, poor publicity and the possibility of fines.

The most common and obvious chemical used in wash bays is the detergent. Many different types of detergent are available on the market with different cleaning strengths and varying costs. Wash bays also use degreasers to clean stubborn oil and grease from the engine compartment. This leaves the vehicle in pristine condition but adds to the oil and grease content of the wastewater stream.

The problem with detergents and degreasers is that they tend to allow oil and water to mix into an emulsion. This creates a major problem for oil water separators. For any oil separator to work, oil must separate from water into bigger and bigger droplets as it rises through the separator. But an emulsion prevents this separation from occurring. The emulsion causes oil and grease to pass straight through the separator and into the sewer.

How can these problems with detergents and degreasers be avoided in wash bays to ensure wastewater compliance?

What is a quick break degreaser or detergent and how do they work?

Quick break degreasers and detergents have a powerful cleaning action to lift dirt off vehicle and engine surfaces. However, they release oil particles almost immediately so that the wastewater stream does not become an emulsion. When this stream reaches the oil water separator, oil is removed from the wastewater, leaving on spec wastewater to be discharged to the sewer.

The reason quick break products are so effective is that they form an electrochemical structure called a micelle. Micelles are very powerful in their detergent properties and are even more effective cleaners than other harsh chemicals that wash bays sometimes resort to using, such as caustic soda [1].

The table below serves as a reference guide for what to look out for in degreasers and detergents.

| Do use | Don’t use |

|---|---|

|

Quick break degreasers |

Emulsion-forming degreasers |

|

Biodegradable products |

Caustic |

|

Non-toxic and non-carcinogenic products |

Metasilicates and salt-based cleaners |

|

Non-reactive products |

Reactive chemicals or chemicals with extreme pH |

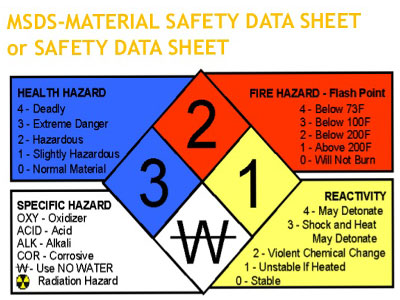

How can I check the properties of my degreaser?

Every chemical is supplied with a Material Safety Data Sheet (MSDS). This is a comprehensive document that describes the properties of the chemical, the hazards associated with it and the way the chemical should be handled and stored.

Keep an MSDS for each chemical used at the wash bay close at hand so that employees can check on any details easily. It is also important to test the performance of detergents and degreasers to verify that they are suitable for their intended application.

Wastewater professionals can conduct tests on the performance of detergents and degreasers to check how long they take to release oil from an emulsified state. Based on the configuration of your wash bay and the length of time wastewater takes to reach your oil water separator, this information can help you determine whether that particular product is suitable for your application.

Best practices for using degreasers with wastewater systems

A few simple steps can make a big difference in the performance of a wash bay wastewater system and their compliance to local council and water authority requirements:

-

Conduct water samples and analysis of inlet and outlet wastewater. This will show whether there are any emulsion problems on the inlet and whether the oil water separator is working as per design.

-

Service wastewater treatment equipment as per manufacturer recommendations. This will ensure that no unforeseen problems result in an environmental incident.

-

Complete pit pump outs regularly. If the pit fills up with oils and solids, it may carry through large slugs of contaminants into the oil water separator. The separator will stop working and an environmental incident will result.

-

Ensure your pits are adequately sized. Quick break degreasers and detergents require settling time ranging from 15-45 minutes before being pumped through an oil water separator. Having an undersized pit can cause the system to pump the wastewater prematurely without the quick break properties taking affect.

Wash bay design is crucial to ensure there is no compliance risk.

Contact Cleanawater

Cleanawater has extensive experience as a wastewater professional. Our technical experts can help you evaluate your detergent and degreaser performance and make recommendations on the right product for your application.

Call us on 1800 353 788 or check out our products and services on our website. We look forward to helping you manage your wash bay wastewater and remain compliant with water authorities.

[1] https://envirofluid.com/info-library/what-is-quick-break-degreaser

Must Read

What to Expect During a Modular Wash Bay Installation

CleanaWater, we make the process of installing a modular wash bay on your site as smooth and straightforward as possible. ...

Read moreThe CleanaWater Team Driving Water Treatment and Sustainability

CleanaWater is powered by a dedicated team of professionals who bring expertise and passion to every project. ...

Read more