An Industry Guide to First Flush Diversion and Wash Bay Compliance

A Simple Solution to Wash Bay Compliance

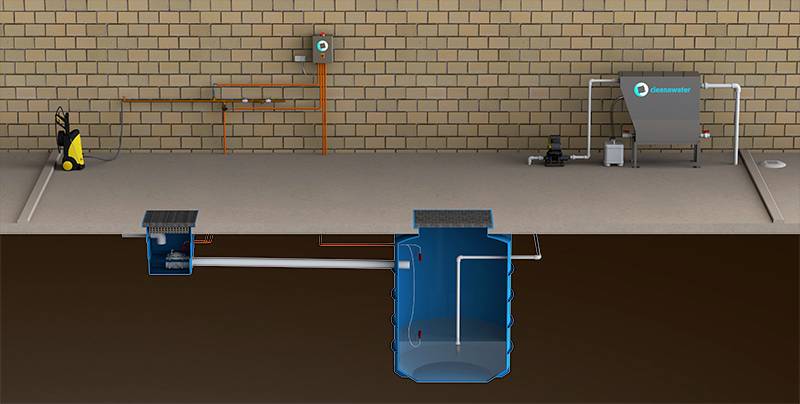

'First Flush Diversion' systems - also known as 'storm water diverters or diversion valves' - are a simple and efficient way to ensure high-risk, contaminated water from commercial or industrial applications is diverted away from stormwater. These systems ensure business operations, such as wash-down bays, are compliant with water authority regulation. Typically, first flush diversion systems are needed in uncovered wash bays over 20 square metres.

Cleanawater's First Flush Diversion systems have been designed to ensure easy maintenance and operation. Our solutions can also be coupled with our water recycling systems and oil water separators for full water authority compliant systems.

At Cleanawater, we specialise in cost-effective, low maintenance, automated, efficient systems for businesses. Call our team on 1800 353 788 to discuss your business' water treatment and compliance needs today, or watch our video on how a first flush diverter can help your business.

What is first flush diversion?

The principle of first flush diversion is that the first 10mm of rain falling onto an unroofed wash bay is considered to be contaminated. This water picks up any residue of oil, sludge, soaps and detergents on the ground surface. It must be routed to a water treatment process like an oil water separator before discharging into a trade waste sewer.

All rainwater falling on a wash pad after the first 10 mm is considered clean and can be routed directly to the stormwater network. In this way, no contaminants are released into the environment, which could cause harm to plants and fish. Another benefit relates to wastewater treatment plants. These plants have defined capacities based on the expected wastewater volumes. Rainwater will overload treatment plants causing them to release contaminated water into the environment.

How does first flush diversion work?

A first flush diversion system has a few key components that enable it to fulfil the diversion function.

A sensor monitors wash gun activation so that the switch to stormwater never happens when the wash bay is operational.

Rain is measured using a rain gauge, which keeps the diverter valve open to the wastewater treatment process until the prescribed volume of rain has fallen. At this point, the diverter valve is shut off and all rainwater overflows into the stormwater system until the valve reactivates.

The diverter valve can be programmed to reactivate based on a number of factors. For example, when a wash gun is activated or when a certain time has lapsed without rain. If the rainfall was insufficient to flush the wash bay, the rain gauge is reset, and the diverter valve remains open.

Features of a Cleanawater First Flush Diversion System

- Ideal for large wash bays without a roof.

- Fully automatic.

- Low maintenance and long operating life.

- Easily coupled with oil water separators and water recycling systems for a complete water compliance solution.

Industry Examples

Example 1: Large Industrial Wash Bay

A business operates a large, un-roofed industrial wash down bay. At the end of each day, dozens of trucks, utility vehicles are washed down after their daily operations.

The local authority has determined the first 10mm of rainwater that falls on the wash pad must be treated before it is discharged to sewerage. the business wishes to install a first flush diversion system to eliminate the requirement for an expensive shed or roof to be constructed above the area.

Solution:

A Cleanawater First Flush Diversion with a rain gauge is an ideal solution.

A rain gauge will measure the first 10mm of rainwater and will divert this amount onto the water treatment system. Once 10mm of rainwater is reached, the gauge will send a signal to the controller and allow further rainwater to be discharged to the stormwater system as the wash pad is deemed flushed of contaminants. The controller can also is designed to automatically detect when hoses and other washing equipment is in operation, allowing this water to be treated before it is discharged to the sewerage.

The First Flush Diversion System can also be combined with a water recycling system. Not only will the company comply with the regulation, it will achieve cost savings from the use of recycled water in operations.

Example 2: Small Commercial Wash Bay

A small, busy wash down bay needs a First Flush Diversion System to comply with the local regulations.

The business requires a simple and low maintenance system capable of handling peak periods of operation. The bay is unroofed and engine and parts degreasing is completed on a daily basis with levels of oils, grease and detergent present in the wastewater. The business realises it’s important that these liquids should not be discharged into the sewerage system.

Solution:

A Cleanawater First Flush Diversion System with rain gauge will suit this business' needs.

The First Flush Diversion System will ensure rainwater is discharged to stormwater or diverted to the water treatment system as required. The diversion system is designed to determine when a wash/degreasing event occurs or when rainfall is falling on the unroofed area

The system is low cost, low maintenance and has a small footprint. The system is also capable of handling peak periods, and operates without the need for a manual controller.

The Parts and Operation of a First Flush Diversion System

Sewerage, Stormwater and Your Business.

To protect oceans and rivers from dangerous substances, water authorities enforce a set of rules regarding the type of substances that can discharged to sewerage or stormwater. To comply with this environmental regulation, a water treatment system is necessary for business activities where harmful chemicals are used. These harmful chemicals, such as detergents, are commonly present at commercial or industrial wash down bays. Once waste water has been treated according to compliance regulation, it can then be safely discharged to the sewer.

Rainwater must not be discharged to sewerage as it overloads the sewerage network. However, when rainwater falls on commercial and industrial sites such as wash bays, it can become easily contaminated with oils and chemicals. Before it can be discharged, this contaminated part of rainwater needs to be treated to remove these harmful chemicals.

It is evident a device is required to divert rainwater to the stormwater discharge and to divert dirty water to the water treatment system.

10mm of Contaminated Rainwater

A number of water authorities estimate that the first 10mm of rainwater is sufficient to flush harmful substances from wash down bay surfaces. Any rainfall over 10mm is deemed clean and suitable to be discharged to stormwater.

First Flush Diversion Systems operate by ensuring the first 10mm of rainfall are diverted to the water treatment system, and rainfall over this amount is diverted to stormwater discharge.

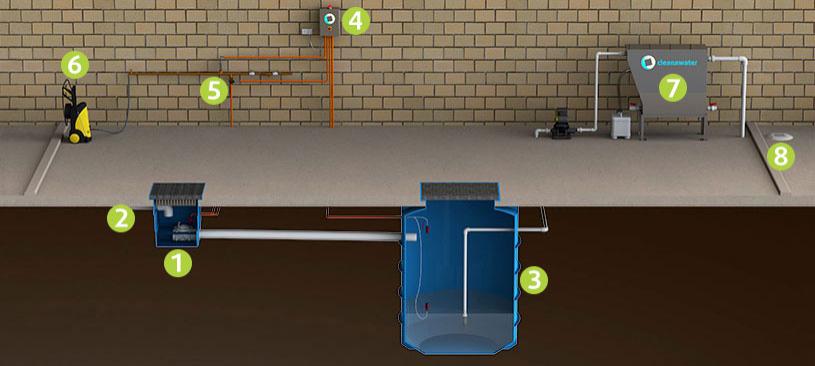

Operation of a First Flush Diversion System

| Number | Description |

|---|---|

|

1 |

All wash water is directed to the Cleanawater Diversion Pit |

|

2 |

Diversion valve shuts allowing discharge to stormwater after 10mm or programmed rainfall amount is exceeded |

|

3 |

Diversion valve open allows contaminated water to flow into main collection pit for further treatment and discharge to authorised discharge point |

|

4 |

Control panel controls the actuation of the diversion valve and/or treatment system if applicable |

|

5 |

Water connection manifold is connected to the diversion valve enabling open/close operation. Valve is electrically or pneumatically actuated depending on the application |

|

6 |

For wash pad applications the pressure washer (supplied by others) resets the diversion valve when a wash operation occurs |

|

7 |

Oil separator treats contaminated water prior to discharge. Commonly paired with diversion systems for a total water treatment solution |

|

8 |

Water is treated and discharged to sewer or approved discharge point |

Get a Custom and Compliant Solution for Your Business

A First Flush Diversion System is an essential technology for commercial and industrial wash down applications. At Cleanawater, we understand that your business requirements are unique; we know that water treatment solutions need to be customised to meet these requirements in a cost-effective and efficient way.

We offer highly technical expertise, excellent quality equipment and a personalised approach to your business' needs. We can easily combine systems, such as First Flush Diversion Systems and Oil Water Separators, to suit your specific business, compliance and investment requirements.

See our First Flush Diversion Systems here, or call our expert team on 1800 353 788 today to discuss efficient solutions for water authority compliance.

Further Reading

How water Recycling Systems Work

Must Read

What to Expect During a Modular Wash Bay Installation

CleanaWater, we make the process of installing a modular wash bay on your site as smooth and straightforward as possible. ...

Read moreThe CleanaWater Team Driving Water Treatment and Sustainability

CleanaWater is powered by a dedicated team of professionals who bring expertise and passion to every project. ...

Read more