No Filter. Just Physics.

Hydrocyclone Oil Separators are an efficient and environmentally-friendly solution for separating oil from water in various industrial applications. These systems play a vital role in protecting the environment by ensuring that harmful oil pollutants are removed from wastewater before it is discharged. In this blog, we will explore how Hydrocyclone Oil Separators work, breaking down the technology behind their design and functionality.

From their internal mechanisms to the factors that affect their performance, you'll gain a comprehensive understanding of how these systems help businesses stay compliant with environmental regulations while maintaining efficient operations.

While Cleanawater doesn't currently stock or service Hydrocyclone Oil Separators, we offer a wide range of Oil Water Separators and Coalescing Plate Separators that are equally effective in managing wastewater.

The Problem: Oil in water

The by-product of some industrial processes is oil-contaminated water, where tiny oil droplets have dispersed within the wastewater solution. Without the right equipment, it is difficult to extract oil from the wastewater so that it is safe to discharge or reuse.

State governments have regulatory bodies in place to ensure that this water is safely managed and discharged. The government enforces wastewater discharge standards and issues fines for non-compliance.

There are a number of ways to remove oil from water, including coalescing oil separation and hydrocyclone oil separation.

About Hydrocyclone Oil Separators

Hydrocyclone Oil Separators apply extreme centrifugal force to separate oil particles from wastewater.

A Hydrocyclone’s primary construction comprises of a conical shaped chamber. This chamber has two exit outlets located at each end with one wastewater inflow inlet on the side. The wastewater enters the cyclone chamber and is spun at centrifugal forces of up to 1000 times the force of gravity.

As the tangential velocity increases, the heavier water phase is forced to the outer wall of the chamber and discharged through the outlet located at the narrow conical end. The lighter oil phase migrates to the centre of the cyclone chamber and is pushed upwards then discharged through the top outlet.

What are the advantages of a Hydrocyclone Oil Separator?

Hydrocyclone Oil Water Separators are a highly effective, compact and low maintenance water filtration solution. This method of separation is ideal for industrial and commercial applications which require high quality filtration of large quantities of water.

-

Compact - Up to 90% smaller than traditional separator system

-

No moving parts means lower maintenence requirements

-

Large flow rates, available from 2,000 to 500,000+ litres per hour

-

Supplied pre-plumbed and pre-wired

-

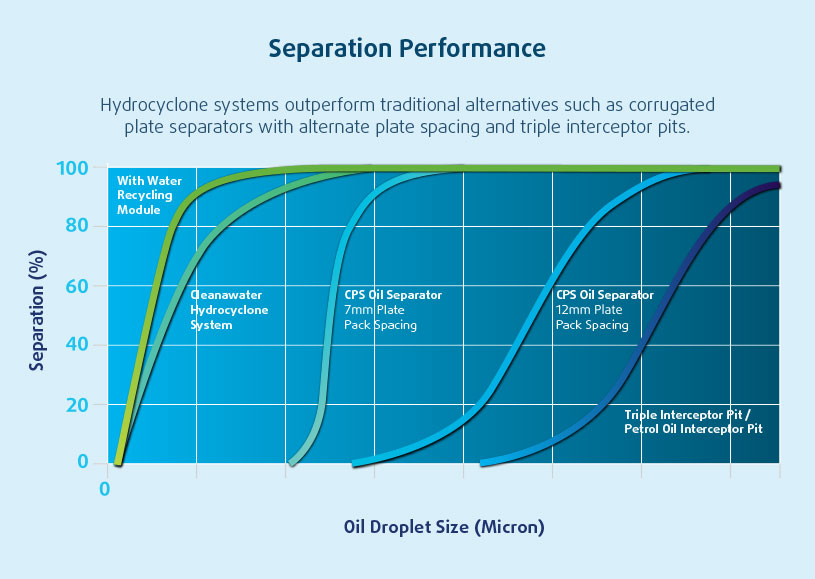

Can remove oil droplets between 10-15 microns. Traditional oil separators function between 40-60 microns.

Cleanawater Hydrocyclones can have additional recycling and pre-treatement modules added to ensure that water treatment processes adhere to certain discharge standard requirements.

Which industries commonly use Hydrocyclone Oil Separators?

Hydrocyclone Oil Separators are widely utilised across a diverse range of industries where oily wastewater is a byproduct of operations. These systems are particularly valuable in sectors such as mining, oil & gas, automotive, manufacturing, and wastewater treatment, where efficient water management is crucial.

In mining and oil & gas operations, Hydrocyclones are used to treat water contaminated with oil from machinery and drilling processes, ensuring compliance with strict environmental regulations. Similarly, the automotive industry relies on Hydrocyclones to separate oil from water in vehicle maintenance and production processes, reducing the environmental impact of wastewater discharge.

Any industry that deals with oily wastewater, whether large-scale or small, can benefit from integrating Hydrocyclone technology to enhance efficiency, reduce costs, and meet environmental standards.

What factors affect the performance of a Hydrocyclone Oil Separator?

The performance of a Hydrocyclone Oil Separator can be influenced by:

-

Flow rate: High flow rates enhance separation efficiency, but exceeding the design capacity can reduce performance.

-

Oil particle size: Larger oil droplets are easier to separate than smaller or emulsified particles.

-

Water viscosity: Lower viscosity water improves separation efficiency. Warmer water tends to improve Hydrocyclone performance as it reduces oil viscosity.

-

Operating pressure: Maintaining the proper pressure ensures optimal centrifugal force for oil-water separation.

Can a Hydrocyclone Oil Separator handle emulsified oil?

No, Hydrocyclone Oil Separators are primarily designed to separate free-floating or non-emulsified oil from water. This type of oil is typically less dense and rises to the surface, making it easier for hydrocyclones to separate through strong centrifugal forces. However, emulsified oil consists of much smaller oil droplets that are dispersed within the water, often stabilised by chemicals or surfactants.

These tiny particles are much harder to separate because they are tightly mixed with the water, creating a stable suspension that doesn’t respond well to the centrifugal action of a Hydrocyclone.

To effectively remove emulsified oil, additional treatment processes such as chemical dosing, which breaks down the emulsion, or coalescing separators, which allow small oil droplets to merge into larger ones, are typically required. These methods are better suited for handling emulsions and are often used in conjunction with Hydrocyclones in complex oil-water separation systems to ensure thorough treatment of wastewater.

Let Cleanawater help with your oil water separator needs

Whether you’re looking for a simple and effective separator or something more comprehensive, Cleanawater are the experts in oil water separators and its process. Call us to discuss your water recycling needs.

Must Read

What to Expect During a Modular Wash Bay Installation

CleanaWater, we make the process of installing a modular wash bay on your site as smooth and straightforward as possible. ...

Read moreThe CleanaWater Team Driving Water Treatment and Sustainability

CleanaWater is powered by a dedicated team of professionals who bring expertise and passion to every project. ...

Read more