What are magnesium hydroxide dosing units?

Why do many solid and liquid waste streams smell like rotten eggs?

Environmental hotlines all around the world are accustomed to receiving calls from community members to complain about odour pollution. One complainant who was stuck at a red traffic light next to a smelly sewer said, “It smells like rotten eggs … It’s awful … you can’t wait for that light to turn green.”

The pungent odour is caused by the presence of Hydrogen Sulphide (H2S) in the air. This H2S is produced by Sulphite Reducing Bacteria (SRB) as they break down sulphite products in the waste stream for energy. So potent is the smell of H2S that it can be picked up at concentrations of less than 1 ppm and it becomes offensive at 3-5 ppm.

Some industries that produce waste containing sulphates, which will be broken down into H2S by bacteria include:

- Municipal wastewater

- Industrial sites

- Landfills

- Solid waste management

- Food and dairy processing

- Abattoirs and tanneries

- Composting

- Meat and livestock

Another negative implication of the presence of H2S is that it is highly corrosive, placing piping and downstream infrastructure at risk of long-term deterioration and failure.

To combat these negative environmental consequences, chemical dosing systems have been developed to treat waste water streams, reducing the H2S content and eliminating odour complaints.

What is a magnesium hydroxide dosing system?

A magnesium hydroxide dosing system specifically targets the production of H2S.

The dosing system consists of a storage vessel for the chemical reagent (in this case magnesium hydroxide), an injection pump and a control panel. Dosing systems are typically located at a sewer manhole, pump station or rising mains. Sometimes injection can even be made directly into a sewer flow stream. The rate of dosing depends on the flow rate of the waste stream.

How does a magnesium hydroxide dosing system work to reduce H2S?

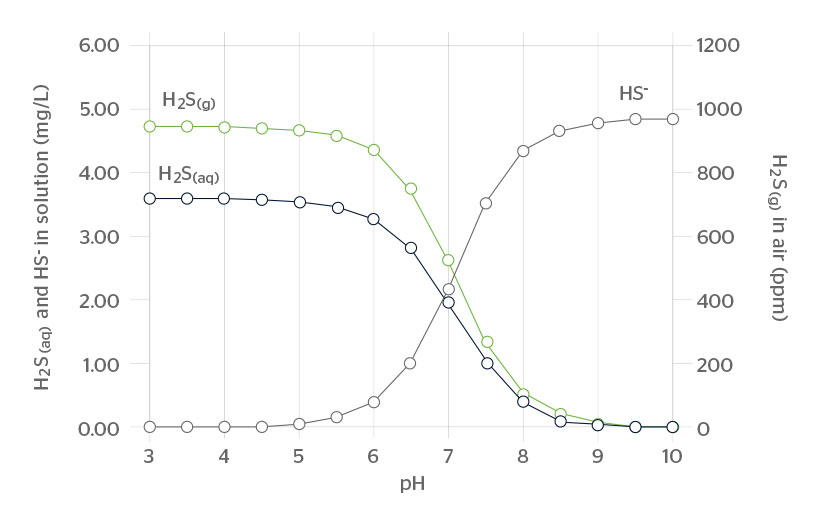

SRBs that produce H2S thrive in specific biological conditions. In addition, the amount of H2S released from the water depends on certain chemical conditions (e.g. dissolved sulphide concentration, water temperature and pH along with the turbulence of flow in the sewers). At a pH of 7, approximately 50% of the dissolved sulphide can exist as H2S, but raising the pH to a level between 8 and 8.5 radically changes the concentrations.

As can be seen in the graph below, dissolved H2S and gaseous H2S are elevated when the pH is below 6, but at a pH greater than 8, sulphides take the form of HS, which remains in solution while the H2S gas tends towards zero. Controlling the pH above 8 through addition of magnesium hydroxide will therefore reduce the presence of H2S and eliminate the offensive odour.

An added advantage is that the higher pH reduces the efficiencies of SRBs so that less sulphides are produced.

Case studies show improved H2S and odour control using Magnesium Hydroxide dosing systems

MidCoast Water

A paper presented at the Water Industries Operators Association of Australia highlights the benefits of magnesium hydroxide dosing systems over alternative methods of odour control. After a number of public complaints of odour, MidCoast Water in NSW conducted trials to determine the effectiveness of magnesium hydroxide dosing. Graphs of the measured H2S concentration in the waste stream show a marked improvement over ferric sulphate dosing, which was previously in use.

Los Angeles

In another high profile case, a number of community groups and organisations filed a lawsuit against the city of Los Angeles due to sanitary sewer overflows and odour problems. The result of this lawsuit was the introduction of a Sewer Odour Control Master Plan for the city. One of the elements of the master plan is magnesium hydroxide dosing into the sewer network on a continuous basis. The report indicates a 90% reduction of H2S in treated sewers achieved through the combined chemical dosing systems. The Odour Control Master Plan for LA is updated annually in order to progressively improve the environmental disturbances to surrounding communities.

Contact Cleanawater for more information about magnesium hydroxide dosing units

Cleanawater has extensive experience in odour management. We treat the odour problem at its chemical cause for a solution that is successful and sustainable. Our technical experts and proven solutions can help your business overcome the challenges of managing odours.

Call our expert team on 1800 353 788 today to discuss efficient solutions for odour control using our state of the art magnesium hydroxide dosing units.

Must Read

What to Expect During a Modular Wash Bay Installation

CleanaWater, we make the process of installing a modular wash bay on your site as smooth and straightforward as possible. ...

Read moreThe CleanaWater Team Driving Water Treatment and Sustainability

CleanaWater is powered by a dedicated team of professionals who bring expertise and passion to every project. ...

Read more