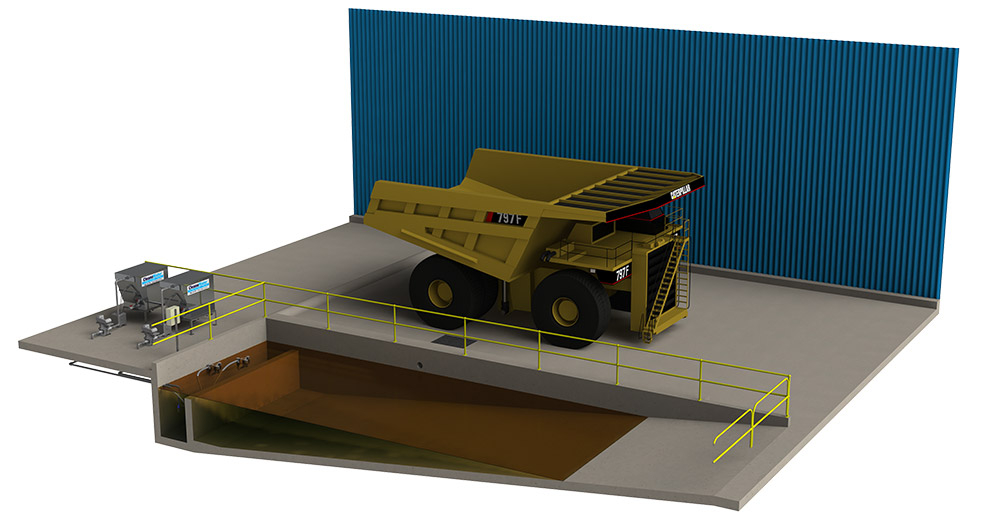

Permanent wash bays tailored to your site

Permanent wash bays are an important tool for businesses to remain in compliance with local water authorities. They go beyond the functionalities of interceptors and oil separators, and provide all-encompassing, permanent solutions for washing vehicles and equipment. Constructed with durable concrete and materials , these wash bays provide a sturdy foundation that meets stringent regulatory requirements while supporting high-volume washing needs.

Specifically designed for your equipment.

Easy access and operation

Can be integrated into existing site infrastructure

Purpose-built authority-compliant wash down areas

Specifically designed for your equipment.

Easy access and operation

Can be integrated into existing site infrastructure

Purpose-built authority-compliant wash down areas

Permanent wash bay benefits

Our permanent wash bays collect and isolate wash water effectively. And when combined with our stormwater diversion systems (for unroofed wash bays), they'll help ensure authority compliance.

- Specifically designed for your equipment

- Purpose-built authority-compliant wash down areas

- Easy access and operation

- Can be integrated into existing site infrastructure

For more information on product specs, site layout diagrams and operation manuals view our document library

Permanent wash bays for all vehicle types

Our permanent wash bays are suitable for all vehicle types, from small cars and trucks to large industrial machinery. Their versatile design allows businesses to wash a variety of vehicles efficiently while maintaining compliance with environmental standards.

Starting a car wash business, get your business off the ground with our extensive guide!

About our permanent wash bays

Cleanawater provides reliable, custom-designed solutions and expert consultation to handle all your wash bay needs. With 20 years of experience in a variety of industries, you can rest easy knowing our permanent systems will take care of your wash-down areas.

Fixed wash bay designs

Permanent wash bays provide an eco-friendly and cost-effective option for keeping your vehicles, machinery or other equipment clean. Save time and money with these long-lasting self-contained washing bays. Our bays protect the environment from potentially harmful wastewater.

Built-in interceptors and oil-water separators capture contaminants, keeping wastewater compliant with environmental regulations. Sloped floors guide runoff to designated drains, reducing standing water and enhancing safety. Additionally, with features like adjustable platforms and high-pressure water systems, fixed wash bays provide a practical and low-maintenance solution for various vehicle cleaning needs.

Why choose a fixed wash bay?

We'll custom-design fixed wash bay systems to your exact requirements. Cleanawater’s wash bay construction means your bay will accommodate the size and weight of your equipment. And it means you may be able to open up new revenue streams from quarantine/AQIS wash down.

- Easy access and operation

- Low daily cost – spread the investment

- Prevent fines and avoid shutdowns

- Purpose-built authority-compliant washdown areas

- Specifically designed for your equipment

Get your operation running smoothly and be compliant-friendly with our flexible financing options. Investing in a Cleanawater wash bay is the smart choice: minimise costs while avoiding fines or shutdowns associated with compliance standards violations.

We can design a wash bay around your requirements

No matter your requirements, we can set you up with the perfect wash down bay for your needs. Some of the design parameters we take into consideration;

- Unroofed

- Roofed

- Indoor

- Outdoor

- Type of machinery/plant being cleaned

No matter what features you’re looking for in your wash bay, our team can design the best system for your site.

Information centre

-

Guidelines for your wash bay water recycling system

Wash bays protect the environment by treating wash down water. We can help you implement wash bay water recycling systems that follow Australian guidelines. -

Our guide to vehicle wash bay design

Find out what elements make for an ideal vehicle wash bay design. We’ll outline the features needed to create compliant portable and permanent wash bays. -

What is the difference between a grease interceptor and oil separator?

Learn the key differences between grease interceptors and oil separators, their functions, and how each device helps protect drainage systems and the environment. -

What Is an oil water separator and how does it work?

An oil-water separator is a device used in wastewater treatment, designed to effectively remove oils and hydrocarbons from water. -

Modular wash bays: clean, green, and flexible

Discover the benefits of Cleanawater's modular wash bay systems, an environmentally friendly solution for efficient vehicle cleaning and maintenance. -

VapourGard: Your ultimate odour control solution

Control odours effectively and safely with CleanaWater's VapourGard system. Ideal for industries such as mining, landfill operations, recycling, and more, the VapourGard system uses lightweight particles to neutralise odours, requires minimal maintenance,

Customer reviews

I have been a plumber for over thirty years and installed many water treatment systems. CleanaWater systems are by far the best for quality and reliability. They provide excellent customer service, from sales staff right through to expert advice and technical help. Can't thank CleanaWater enough!

Iain Paterson, Multilple Trades and Maintenance

We have seen a fantastic improvement since the OdourPro VapourGard™ system was installed 3 years ago. The system mitigates the heavy odours which are released from the site, which has improved conditions for our staff and almost completely eliminated complaints from local residents and businesses

Glenn Claverie, Select Civil

The whole process was very simple, the sales and technical support was great, when needed contact was made easily for assistance during construction and the finished product works and looks fantastic, all in all working with the CleanaWater team to purchase our new Portable Wash Bay was a trouble free process

Doug Neil, Stihl Sales and Service Centre Coffs Harbour

The purchasing of our oil separator, from obtaining a quote through to delivery, was made extremely easy through CleanaWater, the staff are easy to deal with and make the whole process hassle-free, as well as supplying a quality product. I would highly recommend CleanaWater products in the future.

Bret Sheehan, Surefire Plumbing Services

The VapourGard™ system is a great alternative to the other odour suppression systems out there. The unit is easy to use and maintain, does not need a portable water source to dilute the chemical and has a low chemical usage which cuts down on cost.

Nicholas Bhugon, SITA Australia

Cleanawater have been very helpful in getting the solution ordered and out the door to us as quickly as possible. All this in the midst of supply chain issues globally. It’s nice when things still, just, work!

Tom Filipcic, FUCHS Lubricants (Australasia) Pty. Ltd.

In combination with a wide range of operational controls, we have found that complaints from our neighbours have significantly reduced since the VapourGard was installed.

Rebecca Tempest - Manager, Resource Recovery & Waste Services, Blue Mountains City Council

Frequently asked questions

How do I know if my permanent wash down bay complies with local water authorities?

If you have a permanent wash bay already installed at your worksite and you’re unsure if it meets local regulations, contact us today. We'd be happy to get you up to speed and advise on any changes you need to make.

Unroofed, permanent wash bays should prevent untreatedrunoff from entering stormwater drains. They are required by law to have various features, including a holding pit, bunding, diversions systems, and pre-treatment devices. We’ll assess your wash bay area to ensure it meets all requirements.

What's the best way to retain solids from permanent wash bays?

Cleanawater has a range of solutions to separate solids for easy removal from wastewater. Drive-in sumps and beach pits are ideal for permanent wash down solutions that carry a high amount of solids. These components help permanent wash bays collect solids and discharge treated wash water into the environment - making the whole process cleaner and safer.

Do I need any equipment to treat water from permanent wash down bays?

As a rule of thumb, you cannot allow wastewater from permanent wash down bays to discharge directly into wastewater systems. If you have an unroofed permanent wash bay that is larger than 20sqm, you will require a first flush diversion system or similar pre-treatment device.

Can I still install a permanent wash down bay if I don't have sewerage on-site?

You can. Businesses without access to sewerage can use a range of discharge methods approved by local water authorities. These include holding tanks, evaporative ponds, and leach drains.

Businesses located in regional areas may have septic systems. If this is you, contact your local council for accurate advice on where to discharge your treated water.

Do permanent wash bays change equipment depending on the industry?

Yes, permanent wash bays can be customised with different equipment to suit the specific needs of various industries. For example, wash bays for the automotive industry may include high-pressure water systems and brushes for thorough vehicle cleaning, while those designed for construction or mining operations might have heavy-duty mud removal systems and stronger drainage setups.

Industries with stricter environmental standards can integrate advanced oil-water separators and filtration systems. This flexibility in equipment ensures that each wash bay meets the unique cleaning and regulatory requirements of its intended industry.

Can a permanent wash bay be installed in an existing facility?

Yes, a permanent wash bay system can be designed to integrate with existing site infrastructure. This allows businesses to add a compliant wash area without needing to completely overhaul their current operations.

Enquire about our Wash Bays

We have representatives in

Newcastle

Mayfield West

NSW 2304

Sydney

Sydney

NSW 2000

Melbourne

Thomastown

VIC 3074

Brisbane

Geebung

QLD 4034

Perth

Osborne Park

WA 6017

Adelaide

Wayville

SA 5034