The intricacies of oil-water separators

In the industry world, the oil separator is an important tool. It might not get much attention, but it plays a big role in making production efficient while responsibly managing resources. As industries work to balance progress with protecting the environment, it's crucial to understand how these oil separators do their job.

CleanaWater is a leader in this field. We started small but have become experts in solutions for separating oil from water. In this journey, we'll uncover the inner workings of an oil separator.

Come along as we explore the basic principles and smart mechanisms that answer the question: "How does an oil separator work?"

The basics of oil separation

Defining oil separators and their role

Oil separators are important tools in various industries, and they're specialised devices that play a key role in separating oil from water effectively. Their job is crucial for keeping water clean and preventing the environment from being contaminated by oil.

The impact of oil contamination

Oil pollution is a serious danger to underwater ecosystems and fragile environmental harmony. Using these devices to separate oil from water is like a first line of defence to prevent possible environmental harm and disruptions. Now, let's take a closer look at how these crucial separators actually work.

The principles underpinning oil separation

Driving forces of separation

Separating oil and water relies on basic principles that take advantage of the differences between these substances. Key factors like how heavy they are, how thick they are, and how much they naturally stick together form the foundation of this process, leading to the creation of separate phases.

Density, viscosity, and affinity

Because oil is less dense than water, oil rises to the surface, starting the separation process. Viscosity, which is how thick the oil is and how substances are attracted to or repelled by each other (affinity), also makes this separation happen. We uncover the secret to successfully separating oil from water when we grasp these principles.

The mechanics of oil-water separation

The process of separating oil from water involves a complex combination of techniques. Oil separators use these methods to coordinate an effective separation process, resulting in clean water and less environmental harm.

Gravity, coalescence, and filtration

Oil separators use three main methods to accomplish their mission: gravity, coalescence, and filtration. Gravity helps the oil rise to the surface, forming a separate layer. Coalescence encourages tiny droplets of oil to come together, making removing them easier. Filtration, a precise process, captures any leftover impurities, ensuring the water is clear and clean.

Contributions to cleaner streams

These mechanisms work together to remove oil contaminants from water completely. Like different instruments in an orchestra, they operate together harmoniously to ensure the water released is free from oil pollutants that can harm ecosystems.

Oil-water separator variants and their functions

Diverse separator types

Oil-water separators come in various smart designs, each made to handle particular separation challenges. Two notable types are gravity separators and coalescing separators, which showcase these devices' blend of technology and precision.

Gravity separators

Gravity separators use gravity's force to encourage the separation of oil and suspended solids, allowing oil and solids to rise while water settles. This method takes advantage of the difference in density between oil and water, creating clear layers that make it easier to remove any remaining oil.

Coalescing separators

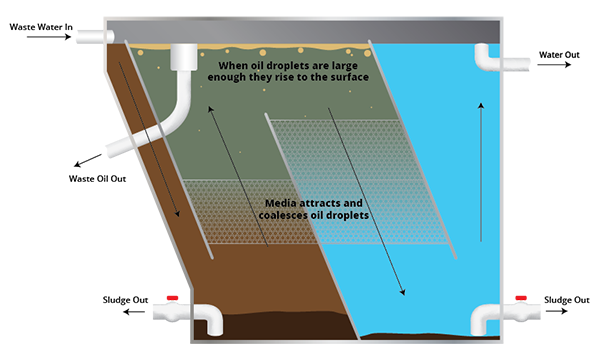

Coalescing separators use coalescence, which is when small oil droplets come together to form bigger ones. These specially designed packs help this process happen, enabling larger oil masses to develop and making separating oil from water more effective.

Precision in action

Each type of oil-water separator uses its own principles to achieve efficient separation. They are designed to handle specific challenges, ensuring that even complex oil-water mixtures can be effectively processed in the oil collecting chamber or in oil tanks.

Understanding oily water separators

Specialised subset

In the world of oil separators, there's a specialised type called an oily water separator. These are designed to tackle the difficulties of an emulsified oily-water mixture, handling complexities that standard separators might struggle with.

Navigating emulsified mixtures

Oily water separators excel at dealing with an emulsified oil-water mixture, where tiny oil droplets are finely spread throughout the water, making regular separation methods ineffective. They work based on the principle of coalescence, where these tiny oil droplets come together to form larger masses, making them easier to remove.

Targeting unique challenges

Oily water separators are designed to tackle the complexities of mixed oil-water combinations. They succeed by prioritising efficient coalescence, making them stand out in situations where standard separators might struggle to keep up.

Industry applications and environmental impact

Versatility across many industries

Oil separators are crucial in diverse industries, including manufacturing, automotive, marine, and oil and gas. Their widespread use highlights their importance for keeping operations running smoothly and protecting the environment.

Eco-friendly endeavours

Efficient oil-water separation plays a vital role in preserving the environment. It stops oil from polluting water bodies, protecting aquatic ecosystems and maintaining the natural balance of our environment.

Regulatory imperatives

Strict regulations emphasise the importance of doing oil separation correctly. These rules are in place to reduce environmental harm, pushing industries to use responsible methods. Following these regulations is good for the environment and ensures that industries contribute to a sustainable future.

Let CleanaWater help you find the perfect oil separator

In exploring how oil separators function, we've uncovered a world of principles and mechanisms that make oil-water separation efficient. This process, although intricate, carries great importance for both industries and the environment.

As you continue exploring this separation technology field, consider CleanaWater's comprehensive wastewater treatment solutions. By collaborating with CleanaWater, you're embarking on a journey that combines progress with environmentally friendly practices, helping you achieve water authority compliance and do right by the planet.

Must Read

What to Expect During a Modular Wash Bay Installation

CleanaWater, we make the process of installing a modular wash bay on your site as smooth and straightforward as possible. ...

Read moreThe CleanaWater Team Driving Water Treatment and Sustainability

CleanaWater is powered by a dedicated team of professionals who bring expertise and passion to every project. ...

Read more