Everything you need to know about wash bay compliance in Melbourne

Operating a wash bay in Victoria comes with significant environmental responsibilities. Whether you’re running a car wash, an automotive workshop, or an industrial facility, ensuring compliance with local regulations is essential to protect waterways and avoid costly penalties. This blog will guide you through everything you need to know about meeting wash bay requirements Victoria businesses must adhere to.

Here’s what we’ll cover:

As it so happens, we’re specialists at designing and installing regulation-compliant vehicle wash bays. Book your consultation with our team for a no-obligation assessment.

Why wash bay compliance matters in Victoria

Wash bay compliance is essential for businesses across Victoria, particularly those in industries like automotive, construction, and mining. Here’s why it matters:

-

Environmental protection: Non-compliant wash bays can discharge untreated wastewater containing oils, chemicals, and sediments into local waterways, posing a significant risk to ecosystems.

-

Legal and financial risks: Businesses that fail to comply with wash bay regulations face fines, legal action, and potential business disruptions.

-

Industry obligations: Meeting Victoria’s stringent environmental standards demonstrates corporate responsibility and helps businesses avoid reputational damage.

Understanding vehicle wash bay requirements in Victoria

Wash bays are essential for businesses in industries like automotive, construction, and industrial manufacturing, where vehicles and equipment need regular cleaning. However, operating a physical wash bay comes with strict environmental responsibilities. Meeting trade waste requirements in Victoria involves adhering to local authorities’ guidelines and EPA Victoria standards to ensure wastewater is properly managed and treated.

Let’s dive deeper into the specific requirements and compliance elements.

Overview of wash bay requirements

Wash bays in Victoria must be designed and operated in line with strict environmental regulations. The key focus is on preventing untreated wash water from entering the environment, protecting both public health and natural resources.

Key compliance requirements include:

-

Drainage systems: All wash bays must have drainage that directs wastewater to appropriate pre-treatment systems, preventing contaminants from entering the stormwater system.

-

Pre-treatment equipment: Oil-water separators, grease traps, and sediment traps are mandatory to treat wastewater before discharge.

-

Wastewater discharge permits (trade waste agreement): Businesses must secure a permit from their local water authority, which outlines specific discharge limits and monitoring requirements.

Each water authority has its own specific requirements, making it essential to consult directly with them to ensure your wash bay project is compliant.

Car wash bay requirements

Car washes generate significant volumes of wastewater containing dirt, grease, oils, and cleaning chemicals. To meet car wash bay requirements, businesses must implement robust systems to manage and recycle water effectively.

Key areas of compliance include:

-

Pre-treatment systems:

-

Oil-water separators to remove hydrocarbons.

-

Sediment traps to capture debris and dirt.

-

Water recycling systems:

-

These systems are critical to reducing water usage and ensuring compliance with environmental regulations. Recycled water must meet strict quality standards before reuse.

-

Special considerations for unroofed wash bays:

-

Unroofed wash bays require additional precautions to manage rainwater runoff, which can carry untreated contaminants into the stormwater system.

-

Chemical use and disposal:

-

Only approved detergents and cleaning agents can be used. Harmful chemicals must be properly treated or disposed of to prevent disruption to wastewater systems.

Penalties for non-compliance:

Failing to comply with car wash bay regulations can lead to:

-

Fines issued by EPA Victoria.

-

Mandatory installation of upgraded treatment systems.

-

Temporary shutdowns or restrictions until compliance is restored.

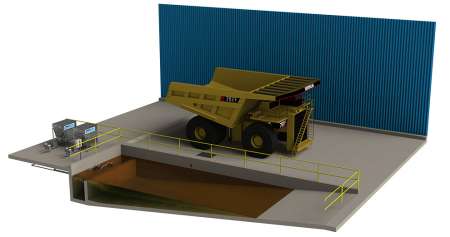

Vehicle wash bay design

The design of your vehicle wash bay significantly impacts compliance. Proper design not only ensures regulatory adherence but also improves operational efficiency and cost-effectiveness.

Essential design elements include:

-

Drainage systems: All wastewater must flow directly to pre-treatment systems to prevent contamination of stormwater.

-

Runoff containment: Contain all water within the wash pad area to prevent environmental leakage.

-

Interceptor pits: These pits capture oils and sediments, ensuring that only treated water is discharged into the sewer system.

-

Sloping floors: Direct wastewater towards drainage points, minimising pooling and preventing overflow.

Best practices for vehicle wash bay design:

-

Non-porous materials: Use durable, non-porous materials for floors and walls to simplify cleaning and prevent seepage.

-

Space considerations: Ensure there is ample space for vehicles and washing equipment to operate efficiently.

A well-designed wash bay not only helps with compliance but also reduces the long-term costs associated with maintenance and system upgrades.

How to ensure your wash bay meets Victorian standards

Pre-treatment systems for effective wastewater management

Installing the right pre-treatment systems is crucial for compliance:

-

Grease traps: Capture fats, oils, and grease.

-

Oil-water separators: Remove hydrocarbons from wastewater.

-

Sediment traps: Prevent debris and sludge from entering the sewer system.

Water recycling solutions for compliance

Water recycling systems are not only a compliance tool but also a cost-saving measure:

-

Reduce water consumption: Recycle and reuse water within your operations.

-

Lower operational costs: Save on water bills and trade waste charges.

-

Support sustainability: Contribute to environmental goals by minimising water waste.

Regular inspections and maintenance

Frequent system checks help maintain compliance and prevent costly breakdowns:

-

Clean interceptors and sediment traps regularly.

-

Inspect water recycling units to ensure proper functioning.

-

Schedule professional maintenance to stay ahead of potential issues.

Common compliance challenges and how to overcome them

Inadequate wash bay design

Poor wash bay design can lead to environmental damage and non-compliance. Upgrading drainage systems and installing the necessary pre-treatment equipment are key solutions.

Insufficient pre-treatment or water recycling systems

Ineffective systems, such as clogged grease traps or underperforming separators, can compromise compliance. Investing in high-quality equipment and regular maintenance resolves these issues.

Lack of knowledge about regulatory updates

Regulations evolve, and staying informed is essential. Working with experts ensures your business remains compliant with the latest standards.

How Cleanawater helps with wash bay compliance in Victoria

Navigating wash bay compliance can be complex, but Cleanawater makes it simple. With over 20 years of experience, we specialise in designing and installing fully compliant wash bays tailored to your business’s unique needs.

Here’s why businesses across Victoria choose Cleanawater:

-

Customised solutions: We design vehicle wash bays to meet the specific cleaning process requirements of industries like automotive, construction, and mining.

-

Integrated systems: Our setups include everything from oil-water separators and grease traps to advanced water recycling units and other specialist equipment.

-

Proven compliance: Our systems meet EPA Victoria and local water authority standards, ensuring your business avoids fines and penalties.

-

Ongoing support: We provide regular maintenance and compliance checks to keep your wash bay running efficiently.

-

Sustainability focus: Our water recycling solutions help reduce water usage and lower your operational costs.

Partner with Cleanawater for reliable, compliant, and cost-effective portable and permanent wash bay solutions.

Must Read

What to Expect During a Modular Wash Bay Installation

CleanaWater, we make the process of installing a modular wash bay on your site as smooth and straightforward as possible. ...

Read moreThe CleanaWater Team Driving Water Treatment and Sustainability

CleanaWater is powered by a dedicated team of professionals who bring expertise and passion to every project. ...

Read more